MECHANICAL SEALS

RJW 1001 RB (REVERSE BALANCE SEAL)

For highly slurry / high viscous liquids / abrasive

services : from low to high pressure &

temperature range.

Design Features

• Externally mounted

• Multiple spring arrangement ensures

uniform spring loading.

• Springs are not in product contact.

• Mechanical loading ensures positive drive

• Independent of direction of rotation.

Rotary : Carbon / silicon carbide / Tungsten

carbide.

Stationary : Tungsten carbide / Silicon carbide

/ Ceramic / Stellite

Hardware Material

Retainer / Springs / Thrust Ring / Grub Screw :

SS316 / Alloys

Secondary Seal Material

Viton / EPR / Buna-n / Neoprene / TTV / Kalrez

O-Ring ensures less shaft fretting due to

capability of flex & roll.

Pressure : Up to 25 Kg / Cm2

Speed : Up to 2900 RPM

Temperature : -20 C to 220 C

RJW 2005 'O' AND 'V' (SINGLE SPRING 'O'/'V')

For Slurry / high viscous liquids / abrasive

services from low to high pressure &

temperature range.

Design Features

• Internally Mounted

• Single coil spring arrangement eliminates

spring clogging.

• Independent of direction of rotation.

Rotary : Carbon / Tungsten carbide / silicon

carbide.

Stationary: Tungsten carbide / silicon carbide /

ceramic / Stellite

Hardware Material

SS 316 / Alloys

Secondary Seal Material

V-Packings / stationary Packing :

PTFE ensures, the seal uasge in mostly all

chemical applications.

Pressure : Up to 11 Kg / Cm2

Speed : Up to 2900 RPM

Temperature : -50 C to 175 C

RJW 2005R 'O' AND 'V' (SINGLE SPRING IN SS RETAINER)

For Slurry / high viscous liquids / abrasive

services from low to high pressure &

temperature range.

Design Features

• Internally Mounted

• Single coil spring arrangement eliminates

spring clogging.

• Mechanical locking ensures positive drive.

• Independent of direction of rotation

Rotary : Carbon / Tungsten carbide / silicon

carbide.

Stationary : Tungsten carbide / silicon carbide /

ceramic / Stellite

Hardware Material

Retainer / Springs / Thrust Ring / Snap Ring /

Grub Screw: SS316 / AlloysSecondary Seal Material

For RJW 2005R ‘W’ : Wedge / Stationary

Packing : PTFE / Glass filled PTFE Wedge

material ensures, the seal usage in high

temperature / chemical applications.

For RJW 2005R ‘O’ Ring : Rotary / Stationary

‘O’ Ring : Viton / EPR / Buna-n / Neoprene ‘O’

ring ensures less shaft fretting due to capability

of flex & roll. ‘O’ rings seals are more preferred,

wherever elastomer is suitable to process fluid.

Pressure : For RJW 2005R ‘O’ / ‘W’ :

Up to 11 Kg to 30kg / Cm2

Speed : Up to 2900 RPM

Temperature : -50 C to 200 C

RJW 3001 (RUBBER BELLOW SEAL)

For light chemical duties ranging from water to

weak acid solutions, wherever Elastomer is

suitable.

Design Features

• Single coil, ealstomer bellow eliminate

clogging.

• Single unit without any loose component

ensures easy & accurate assembly.

• Compact design permits to install within

limited dimension of stuffing Box.

Rotary : Carbon / silicon carbide.

stationary : Silicon carbide / High Alumina

Ceramic 99.5%

Hardware Material

SS 316

Secondary Seal Material

Elastomers :

Viton / EPR / Buna-n / Neoprene

Pressure : 15 Kg / Cm2

Speed : Upto 2900 RPM

RJW 4001 (TEFLON BELLOW SEAL)

For highly corrosive clear / abarasive liquids

from low to medium pressure.

Design Features

• All wetted parts are non metalic.

• Extremely Mounted

• Multiple spring arrangement ensures

uniform spring loading.

• Independent of direction of rotation.

Rotary : Glass filled Teflon (GFT)

Silicon Filled Teflon (SFT)

Stationary: Ceramic / Silicon carbide

Hardware Material

Retainer : Glass filled PTFE

Springs : Alloys

Thrust Ring : SS316

Allen Bolt : SS316

Clamp Ring : SS316

Mating Ring Packing : PTFE

Secondary Seal Material

Ceramic / SIC / TC

Pressure : 9kg / Cm2

Speed : Up to 2900 RPM

Temperature : -40 C to 120 C

In Gland Rope Average Leakage 90 Drop / minute

Or 5400 Drop/hr

Or 2.3galleon (8.6 Litre) Per Day

Or 833 Galleon (3153 Litre) Per Year

In Mechanical Seal to Small to Measure/ Minute

Average 5 Drop Per Hour

or 120 Drop Per Day

or 0.8 Galleon (2.9 Litre) Per Year

or 0.8 Galleon (2.9 Litre) Per Year

5400 Drop Per Hour%5drop Per Hour=1080

Ratio = 1:1080

1microne = 1 Millionth of Meter = .001mm

1l.b. = 1.11 Lakh’s of An Inch Approximately = 0.000016″

2l.b. (light Band) = 23.2 Millionth of An Inch

3l.b. = 0.00884mm = 0.001mm = 1microne

Nacked Eye Can See upto 100 Mircone

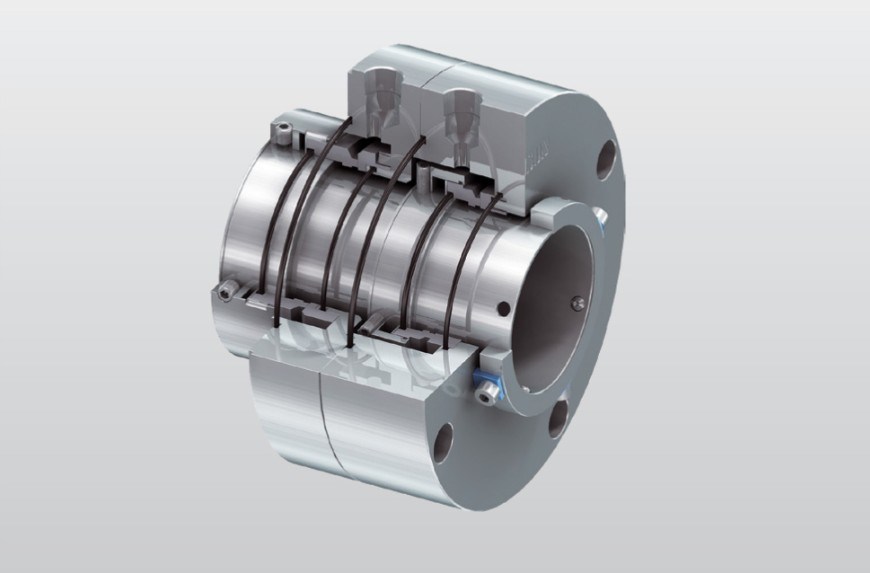

RJW 8001CRT (SPECIAL CARTRIDGE TYPE SINGLE/MULTI SPRING SEALS)

For liquid of crystallizing nature / slurry / high

viscous liquids / abrasive services of low & high

pressure & temperature range.

Design Features

• Spring provided in stationary part

eliminates spring clogging & seal hang up.

• Mechanical loading ensures positive drive

• Independent of direction of rotation.

• Face combination selected ensures

extended seal life in abrasive services.

• stationary part provided with springs do

not flex on every revolution, ensure better

life of secondary sealing, can work for

high shaft speed.

Mostly Used in following Industries :

Paper & Pulp Plant

Alcohol Distilleries

Pharmaceutical Industries

Rotary : Carbon / Tungsten carbide / Silicon

carbide

Stationary : Tungsten carbide / Silicon carbide

/ Ceramic

Hardware Material

Rotary & stationary cage / Springs / Grub

Screw: SS 316/Alloys

Secondary Seal Material

Rotary / stationary ‘O’ Ring :

Viton / EPR / Buna-n / FEP / Neoprene / PTFE

enveloped elastomer ‘O’ Ring ensures less

shaft fretting due to capability of flex & roll.

Pressure : 35 Kg / Cm2

Speed : Up to 2900 RPM

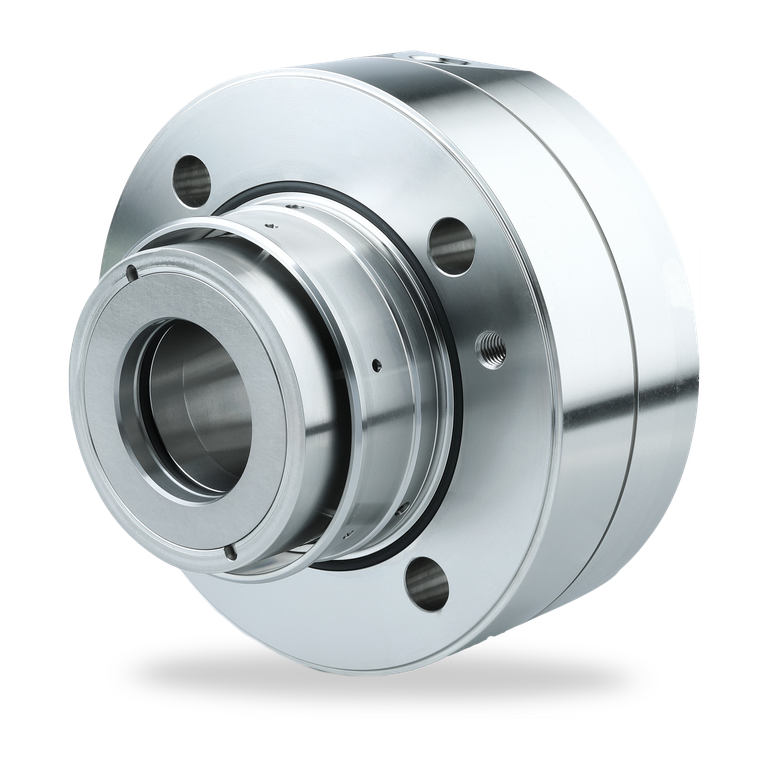

RJW 5100/5200 (DOUBLE/SEAL AGITATOR SEALS)

For Agitators / Mixers / Vessels / Auto Claves

Design Features

• Top entry drive.

• Cartridge Construction.

• Independent of direction of rotation.

• Optional design available to match the

pressure level.

• Seal can be supplied with reverse

pressure balance Single Seal.

Rotary : Carbon / Silicon carbide / Tungsten

carbide

Stationary : Ceramic / Silicon carbide /

Tungsten carbide / Stellite

Hardware Material

Retainer / Springs / Thrust Ring / Grub Screw:

SS 316/Alloys

Secondary Seal Material

For RJW 5100 : Wedge / stationary packing :

PTFE / Glass filled PTFE / Graphite Wedge

material ensures, the seal usage in high

temperature / chemical applications.

For RJW 5200 : Rotary / stationary ‘O’ Ring :

Viton / EPR / Buna-n / Neoprene / FEP / Kalrez

‘O’ Ring ensures less shaft fretting due to

capability of flex & roll. ‘O’ ring seals are more

preferred, wherever elastomer is suitable to

process fluid.

Pressure : RJW 5100 : Up to 11 Kg/Cm2

: RJW 5200 : 40 Kg/Cm2

Temperature : -20 C to 300 C